Emergency One, a leading UK manufacturer of fire and rescue vehicles and creator of the world’s first fully electric fire engine are going to work in partnership with Smart Manufacturing Data Hub (SMDH) Rapid Demonstrator awardee, Booth Welsh.

The company will be installing energy monitoring sensors and the Booth Welsh Energy Monitoring dashboard in their Ayrshire site to gain better insights into their energy usage and emissions.

Building on their world’s first electric fire appliance, Emergency One is producing a prototype of a hydrogen fuel cell-powered fire appliance, with the goal of promoting the adoption of clean energy solutions in the emergency services sectors.

“Rising Energy Costs are forcing us to find new ways to streamline the efficiency of our operations”

Speaking about the project, Emergency One Compliance Manager, Stewart Gorman said, “As with all manufacturers, rising energy costs are forcing us to keep looking for ways to streamline the efficiency of our operation. Our commitment to become a Net Zero business and leading provider of low emission vehicles to the emergency services sectors is driving us to become better informed about our energy usage and emissions.

This is what we hope to achieve by taking part in this SMDH Rapid Demonstrator project with Booth Welsh. We were also pleased to have this opportunity to collaborate with another local Ayrshire company who are at the forefront of innovation and digitalisation”.

“We can engineer a better future through collaborations like this”

Consultancy Services Director, Gordon Semple said “At Booth Welsh we believe we can engineer a better future through collaborations like this. The opportunity to work alongside a local innovative company who share our values in sustainable practices and setting the pace for a low carbon future is both exciting and necessary. We look forward to working with Emergency One on this project to help them gain the insights they need into their energy usage and emissions and provide us with valuable feedback to make the Energy Monitoring Dashboard an essential business intelligence tool for the manufacturing industry.”

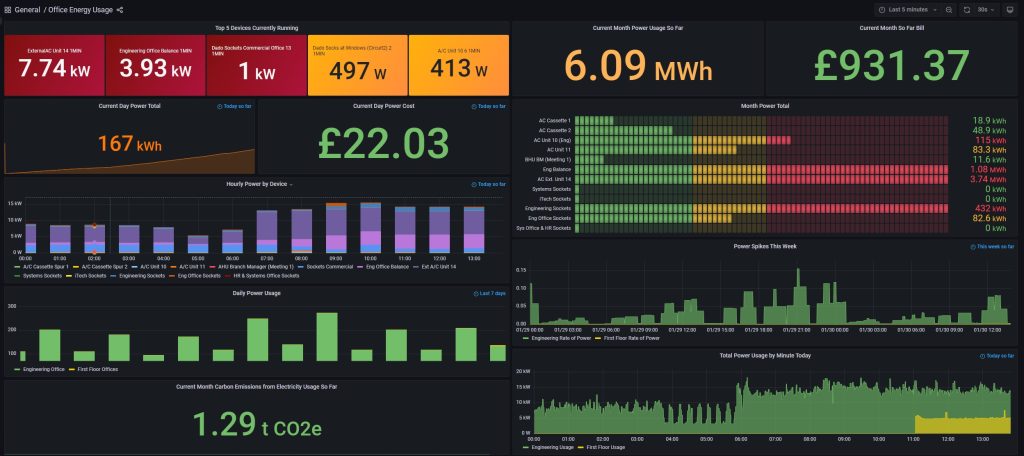

Snapshot of the Energy Monitoring Dashboard being installed at Emergency One

The system measures the energy usage of the devices connected on the site. This is achieved by means of IIOT sensors, which are installed either at the distribution board or local to the machine or asset. The energy usage data from the sensors is relayed to the central database via a wireless network, which is then displayed on a dashboard. This dashboard can be displayed via any device on the network via an internet browser.

We look forward to updating you on the progress of this exciting project in the coming weeks. If you have any questions or would like to get involved, please don’t hesitate to contact the team today.